The range of Carbolite Gero horizontal rotating tube furnaces offers the benefits of simultaneous heating and mixing of the sample, in addition to the use of an inert atmosphere.

RHST & RHZS – Rotating Horizontal Split Tube Furnaces

Description

The furnaces are suitable for continuous material processing. Residence time in the heated zone depends on the degree of inclination and the rotating speed (which can be controlled by the customer) and the length of the working tube, in addition to the flow properties of the material. The design of the split furnace, drive system and feeder/ collection assemblies allows the work tube to be easily removed and replaced.

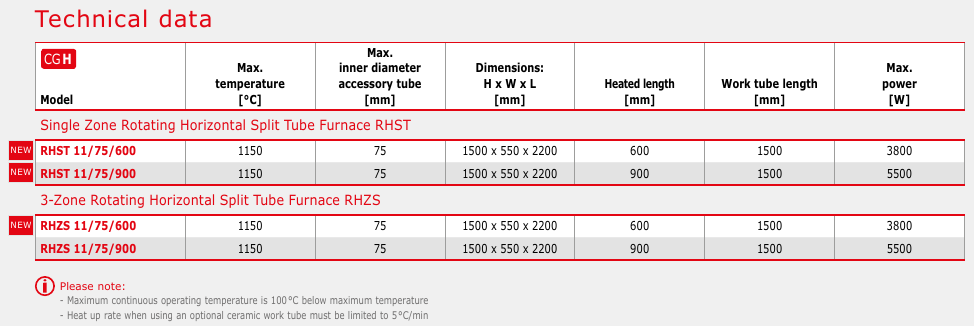

The single zone and 3-zone split tube furnaces have a maximum operating temperature of 1150°C. All models are available with heated lengths of either 600 mm or 900 mm. The angle of inclination can be easily adjusted between horizontal and 10°. The ceramic (IAP) work tube has an inner diameter of 75 mm. A safety switch automatically prevents heating and tube rotation when the furnace is opened.

It is essential to discuss your application with Carbolite Gero to ensure the suitability of the material for use in this equipment. Carbolite Gero cannot accept responsibility for your process due to the possibility of the material becoming sticky when heated and therefore not flow through the work tube.

Standard features

• 1150°C maximum operating temperature; normal operating temperature range 650°C – 1050°C

• 3-zone models fitted with Carbolite Gero 301 digital PID controller with single ramp to setpoint, digital display and process timer for centre zone. End zone control is provided

by 2132 slave controllers

• 5 litre capacity vibratory feeder and hopper

• Accepts work tube with inner diameter of 75 mm

• Adjustable inclination and rotation speeds offers flexibility of residence time

• Heated lengths of 600 mm and 900 mm

• Single zone models fitted with Carbolite Gero 301 PID controller with single ramp to setpoint

• Single or 3-zone models

• The temperature controllers and associated equipment are housed within the integral control box

• Wire elements in high quality vacuum formed insulation ensure fast heat up, excellent temperature uniformity and short cool down times

• Work tube rotation speed 1.5 to 10.0 revolutions per minute

Options (specify these at time of order)

• 5 litre capacity heavy duty vibratory feeder and hopper

• Inert gas packages available on request

• Quartz (up to 1100°C) or metallic (up to 800°C) work tubes

Order now

To make your order, please contact us at info@polyscientific.com.my or call us at +6 06 3350 690