For innovative microbeads and microcapsules

Encapsulator B-390

Description

The versatile system for controlled encapsulation of active ingredients and materials for laboratory-scale research and development work. The simplicity and adaptability of the device allow its use in a variety of areas – pharmaceuticals, materials, cosmetics, the food industry and agriculture.

Benefits :-

Reliable

• Efficient, reproducible encapsulation process

• Exceptionally tight particle size distribution

• High encapsulation efficiency and high yields

User Friendly

• Intuitive to operate and easy to maintain

• Quick and easy process optimization thanks to visualization of droplet formation

• The BUCHI application database and BUCHI application support help you get the most out of working with the Encapsulator B-390

Versatile

• Choice of particle diameters between 80 μm and 4000 μm

• Production of monodisperse microbeads and microcapsules

• Suitable for the encapsulation of microorganisms, organic and inorganic substances

Features :-

• Big capsules nozzle – Nozzle system for production of large core-shell capsules (dia. 2 – 4 mm) by means of drop separation process.

• Concentric nozzle system – Concentric nozzle system for creating core-shell capsules (dia. 200 – 2000 µm).

• Flow vibration nozzle – Airflow-assisted nozzle system for producing beads (dia. 80 – 1000 µm) from highly viscous polymers.

• Nozzle heating – The integrated nozzle heater expands the breadth of applications. It enables the processing of melts such as wax or gelatine.

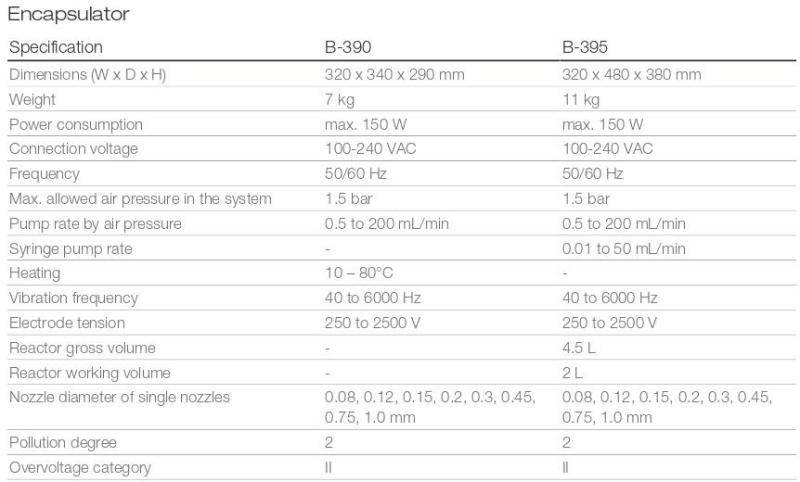

Technical Data

Video

Order now

To make your order, please contact us at info@polyscientific.com.my or call us at +6 06 3350 690